Vacuum Dryers

Vacuum drying is ideal for materials that would be damaged or changed if exposed to high temperatures. The vacuum removes moisture while preventing the oxidation or explosions that can occur when certain materials combine with air. Vacuum drying is also ideal in situations where a solvent must be recovered or where materials must be dried to very low levels of moisture.

Vacuum Drying Saves Time

Unlike atmospheric drying, drying under reduced pressure lowers the boiling point and provides a greater temperature difference between the heating medium and product. This results in faster drying and more efficient heat recovery.

Unlike atmospheric drying, drying under reduced pressure lowers the boiling point and provides a greater temperature difference between the heating medium and product. This results in faster drying and more efficient heat recovery.

Vacuum Drying Saves Money

Drying at lower temperatures reduces energy consumption. The dryers' closed-system design allows costly solvents to be recovered, eliminates expenses for additional air pollution control or exhaust systems, and minimizes product loss caused by atmospheric contaminants, dusting, oxidation, discoloration, and chemical change.

Drying at lower temperatures reduces energy consumption. The dryers' closed-system design allows costly solvents to be recovered, eliminates expenses for additional air pollution control or exhaust systems, and minimizes product loss caused by atmospheric contaminants, dusting, oxidation, discoloration, and chemical change.

Vacuum Drying Protects Workers

Since drying occurs in a closed system, hazardous materials and fumes are not released into the air. The potential for explosions is reduced because of the lower temperatures and the lack of dust and air in the dryer.

Since drying occurs in a closed system, hazardous materials and fumes are not released into the air. The potential for explosions is reduced because of the lower temperatures and the lack of dust and air in the dryer.

Shelf Vacuum Dryers

McGill AirPressure shelf vacuum dryers are designed for drying materials that must not be agitated or that are processed in small batches. The material is loaded into pans or other containers, which are placed on heated shelves. Standard shelves are designed for 30, 50, or 100 psig, coincidental with full vacuum in the dryer. The heating medium is usually steam or water, but oil or another high-temperature fluid can be used.

McGill AirPressure offers more than 50 standard sizes of shelf dryers, with shelf areas from 2 to 1,000 square feet. We can also custom design and manufacture a shelf dryer to meet your size requirements. Standard units are rectangular with casings and shelves fabricated from carbon steel, stainless steel, or special alloys. Glass bead blasting and various types of polishing are options for finishing the casings and shelves. A variety of industrial coatings including Plasite, Heresite, and Teflon can be applied to the dryer internals.

Shelf Drying Applications:

- pharmaceuticals

- chemicals

- plastics

- food products

- ceramics

- eletrical/electronic components

Shelves

Each dryer shelf is constructed of a baffle and side enclosure bar sandwiched between two steel plates. The flat heating shelves allow maximum pan contact with minimum temperature variation. They are heated by an internally circulating fluid, with large headers allowing uniform flow through all shelves. Heating fluid connections between the headers and the heating shelves provide vacuum-tight service and make the shelves easy to remove. They can be located at the front or the rear of the shelves. Standard shelves are designed for 30, 50, or 100 psig internal pressure, coincidental with full vacuum in the drying chamber. Customized shelves can be built to the customer's specific pressure requirements.

They can be fabricated to meet ASME code standard.

Doors

Dryer doors are reinforced to reduce deflection under vacuum pressure. A parabolic door gasket is set in a machined dovetail groove to provide a tight seal. Doors are equipped with heavy-duty hinges to withstand constant use. Hinges can be set on either the right or the left side. Tempered sight glasses can be built into doors to allow operators to view the product as it is being dried.

Construction

Drying chambers are made of reinforced carbon steel for durability. To resist corrosion inside the drying chamber, internals can be fabricated of stainless steel, special alloys, or coated with baked phenolic resins. External surfaces can be painted or given a bead-blasted finish. External insulation sheathing is available in carbon steel or stainless steel and can be seam welded or joined with sheet metal screws. Sheathing is available with a commercial mill, polished, or painted finish.

Auxiliary Equipment Options for Shelf Vacuum Dryers

Vacuum gauge, vacuum release valve, thermometer, or pressure gauge

Vertical shell and tube surface condensers

Refrigerated or dry-ice traps

Vacuum pumping systems: mechanical, water-sealed, or steam jet

Heating systems: steam, water, oil, or other fluid

Cooling systems: direct or indirect

Extra connections

Special casing or shelf arrangements

Product pans (trays) fabricated of carbon steel, stainless steel, and other alloys

Instrumentation for process control and documentation: fully wired control panels or field mounted individual instruments for sensing, indicating, or recording temperature, pressure, and other variables

Complete systems with components assembled on a common baseplate

Standard Specifications for McGill AirPressure Shelf Vacuum Dryers

| Model | # of Usable Shelves | Shelf Area (sqft) | Shelf Spacing (in) | Shelf Size W x D (in) | Approximate Outside Dimensions (ft) | Approx. Weight (lb) | ||

|---|---|---|---|---|---|---|---|---|

| H | W | D | ||||||

| 1A | 2 | 2.25 | 3 | 12 x 13 1/2 | 2 | 2 | 2 | 700 |

| 2B | 2 | 9.50 | 6 | 29 x 23 1/2 | 5 | 3 1/2 | 3 1/2 | 1,850 |

| 2B | 3 | 14.20 | 3 5/8 | 29 x 23 1/2 | 5 | 3 1/2 | 3 1/2 | 2,000 |

| 2B | 4 | 18.90 | 2 1/2 | 29 x 23 1/2 | 5 | 3 1/2 | 3 1/2 | 2,150 |

| 3B | 5 | 23.70 | 5 3/8 | 29 x 23 1/2 | 5 | 3 1/2 | 3 1/2 | 2,850 |

| 3B | 6 | 28.40 | 4 3/8 | 29 x 23 1/2 | 5 | 3 1/2 | 3 1/2 | 3,000 |

| 3B | 7 | 33.10 | 3 1/2 | 29 x 23 1/2 | 5 | 3 1/2 | 3 1/2 | 3,100 |

| 4C | 6 | 36.00 | 5 | 24 x 36 | 5 1/2 | 3 1/2 | 3 1/2 | 3,500 |

| 4C | 7 | 42.00 | 4 | 24 x 36 | 5 1/2 | 3 1/2 | 3 1/2 | 3,700 |

| 4C | 8 | 48.00 | 3 1/2 | 24 x 36 | 5 1/2 | 3 1/2 | 3 1/2 | 3,850 |

| 5D | 3 | 34.70 | 5 | 39 1/4 x 42 1/2 | 5 | 5 | 5 1/2 | 3,600 |

| 5D | 4 | 46.30 | 3 1/2 | 39 1/4 x 42 1/2 | 5 | 5 | 5 1/2 | 3,900 |

| 5D | 5 | 57.90 | 2 1/2 | 39 1/4 x 42 1/2 | 5 | 5 | 5 1/2 | 4,150 |

| 6D | 6 | 69.50 | 3 5/8 | 39 1/4 x 42 1/2 | 5 | 5 | 5 1/2 | 4,800 |

| 6D | 7 | 81.00 | 3 | 39 1/4 x 42 1/2 | 5 | 5 | 5 1/2 | 5,100 |

| 6D | 8 | 92.60 | 2 1/2 | 39 1/4 x 42 1/2 | 5 | 5 | 5 1/2 | 5,350 |

| 7D | 9 | 104.20 | 4 3/8 | 39 1/4 x 42 1/2 | 6 1/2 | 5 | 5 1/2 | 6,850 |

| 7D | 10 | 115.80 | 3 7/8 | 39 1/4 x 42 1/2 | 6 1/2 | 5 | 5 1/2 | 7,150 |

| 7D | 11 | 127.40 | 3 1/2 | 39 1/4 x 42 1/2 | 6 1/2 | 5 | 5 1/2 | 7,450 |

| 7D | 12 | 139.00 | 3 | 39 1/4 x 42 1/2 | 6 1/2 | 5 | 5 1/2 | 7,700 |

| 7D | 13 | 150.60 | 2 3/4 | 39 1/4 x 42 1/2 | 6 1/2 | 5 | 5 1/2 | 8,000 |

| 8D | 12 | 139.00 | 4 3/8 | 39 1/4 x 42 1/2 | 8 | 5 | 5 1/2 | 8,600 |

| 8D | 14 | 162.10 | 3 1/2 | 39 1/4 x 42 1/2 | 8 | 5 | 5 1/2 | 9,200 |

| 8D | 16 | 185.30 | 3 | 39 1/4 x 42 1/2 | 8 | 5 | 5 1/2 | 9,750 |

| 9E | 9 | 110.00 | 4 | 44 x 40 | 5 1/2 | 5 1/2 | 6 | 7,150 |

| 9E | 11 | 134.40 | 3 | 44 x 40 | 5 1/2 | 5 1/2 | 6 | 7,800 |

| 9E | 13 | 158.90 | 2 1/2 | 44 x 40 | 5 1/2 | 5 1/2 | 6 | 8,400 |

| 9E | 15 | 183.00 | 2 | 44 x 40 | 5 1/2 | 5 1/2 | 6 | 9,000 |

| 10E | 18 | 220.00 | 2 5/8 | 44 x 40 | 8 1/2 | 5 1/2 | 6 | 10,850 |

| 10E | 20 | 244.40 | 2 1/4 | 44 x 40 | 8 1/2 | 5 1/2 | 6 | 11,500 |

| 10E | 22 | 268.80 | 2 | 44 x 40 | 8 1/2 | 5 1/2 | 6 | 12,100 |

| 11F | 12 | 192.30 | 4 3/8 | 59 x 39 1/8 | 8 | 6 1/2 | 5 | 10,950 |

| 11F | 14 | 224.40 | 3 1/2 | 59 x 39 1/8 | 8 | 6 1/2 | 5 | 11,750 |

| 11F | 16 | 256.40 | 3 | 59 x 39 1/8 | 8 | 6 1/2 | 5 | 12,550 |

| 11F | 19 | 304.50 | 2 3/8 | 59 x 39 1/8 | 8 | 6 1/2 | 5 | 13,700 |

| 12G | 9 | 290.30 | 4 3/8 | 59 x 78 3/4 | 7 | 6 1/2 | 9 | 16,750 |

| 12G | 10 | 322.60 | 3 7/8 | 59 x 78 3/4 | 7 | 6 1/2 | 9 | 17,500 |

| 12G | 12 | 387.10 | 3 | 59 x 78 3/4 | 7 | 6 1/2 | 9 | 19,050 |

| 12G | 14 | 451.70 | 2 1/2 | 59 x 78 3/4 | 7 | 6 1/2 | 9 | 20,500 |

| 13G | 12 | 387.10 | 4 3/8 | 59 x 78 3/4 | 8 | 6 1/2 | 9 | 20,600 |

| 13G | 14 | 451.70 | 3 1/2 | 59 x 78 3/4 | 8 | 6 1/2 | 9 | 22,150 |

| 13G | 16 | 516.20 | 3 | 59 x 78 3/4 | 8 | 6 1/2 | 9 | 23,700 |

| 13G | 19 | 613.00 | 2 3/8 | 59 x 78 3/4 | 8 | 6 1/2 | 9 | 26,000 |

| Larger sizes are available upon request. | ||||||||

Replacement Parts and Services

We stock a wide variety of parts for J.P. Devine and McGill Vacuum Dryers. We can also custom fabricate parts from our drawing and data archives for dryers manufactured from 1950 to present.

Parts and Service:

Replacement parts, inspection, preventive maintenance, code repairs, emergency repair servce, coating repairs and replacement, rebuilds and upgrades, and control system upgrades.

Gaskets:

We stock replacement gaskets for all types of pressure vessels manufactured by McGill AirPressure and United McGill, including Biggs autoclaves and J.P. Devine vacuum dryers. These are McGill AirPressure parts, made to McGill AirPressure specifications.

With our in-house splicing machine, we cut and splice gaskets to fit your equipment. Don't wait until you've blown your last gasket. Keep a supply on hand to get your equipment back in operation as fast as possible.

Technical Know-How

Use the chart below to find the gaskets you need. The chart shows standard gaskets in stock. If your type is not shown, we can arrange for custom tooling of an extrusion die and selection of a compound for your application.

Let us help you choose the right gasket type, size, and material. We provide free installation instructions for all gaskets we carry.

| Gasket Cross Section | Order Code |

|---|---|

|

G211 |

| G212 | |

| G213 | |

|

G214 |

|

G215 |

|

G216 |

|

G217 |

|

G218 |

|

G219 |

Rotary Vacuum Dryers

McGill AirPressure designs and manufactures rotary vacuum dryers for drying difficult or sticky materials that can withstand agitation. Drying takes place in a cylindrical chamber with an internal agitator. Vacuum dryers remove moisture by exposing the materials to reduced pressure. Just enough heat is used to replace that lost through vaporization

The jacketed shell is horizontal and cylindrical in shape. A double-flight of spiral ribbon or heavy-duty paddles is attached to a rotating shaft inside the dryer. During operation, the ribbons or paddles move material from the center of the dryer to the end plates and back so that the batch is constantly exposed to the heated shell and shaft. This action also allows for ready discharge.

The shell and shaft are heated by steam, water, oil, or another high-temperature fluid. Standard working volumes range from 2 to 300 cubic feet. Rotary dryers are fabricated from carbon steel, stainless steel, or special

Rotary Drying Applications:

- pharmaceuticals

- chemicals

- food products

- filter cakes

- pastes

- slurries

- heavy, sticky products

Material Handling

Material is loaded into the drying chamber by means for a charge nozzle with a spring-assisted, hinged cover. The discharge valve can be designed for handwheel, air, or hydraulic operation. Parabolic charge and discharge gaskets are set in a machined dovetail groove. Large-diameter, flanged vacuum connections prevent atmospheric contamination and allow optimum conductance. Clean-out ports can be built into the dryer's end plates.

Rotary Vacuum Dryer Operation

Rotary dryers are designed for standard operating vacuums up to 10 torr. Constant-speed and variable-speed drives are available in chain-and-sprocket, gear-and-pinion, or direct-drive designs with guards, fan-cooled enclosures, and torque couplings. Dryers can be equipped with self-aligning, anti-friction, pillow block-type bearings and special motor enclosures.

During operation, the material being dried is mixed by a heated spiral ribbon or paddle agitator. Each agitator is durably constructed with the spiral inner and outer ribbons or paddles welded to support arms on the center shaft. For larger models, the agitator shaft is heated by a rotary union and siphon pipe. The agitator shaft is sealed by stuffing box assemblies.

For operating vacuums below 10 torr, the shaft can be equipped with double mechanical seals.

Construction of Rotary Vacuum Dryers

Rotary dryers are available with all vapor-contacting parts made of carbon steel, stainless steel, or special alloys. Internal shell and external agitator welds are ground smooth and flush. External surfaces are painted; interior surfaces can be polished.

The dryer's jacket can be designed and stamped in accordance with ASME code for 25, 50, or 100 psig, conicidental with full vacuum in shell. The jacket is baffled for equal distribution of liquid heating mediums. External insulation and sheathing can be seam welded and polished or joined with sheet metal screws.

Rotary dryers are equipped with a vacuum gauge, vacuum release valve, jacket pressure gauge, and jacket relief valve. A product thermocouple well is available. Standard and special saddle supports are available.

Each rotary dryer is fully assembled and vacuum leak tested at McGill AirPressure's manufacturing plant.

Auxiliary Equipment Options for Rotary Vacuum Dryers

Vertical shell and tube surface condensers

Vacuum pumping systems: mechanical, water-sealed, or steam jet

Heating systems: steam, water, oil, or other fluid

Cooling systems: direct or indirect

Bag-type vacuum dust collectors with controls for intermittent shaking or pulsing of material back into the dryer

Dust-tight discharge hoppers and valves for filling containers

Flush-type clean-out ports in end plates

Instrumentation for process control and documentation: fully wired control panels or field mounted individual instruments for sensing, indicating, or recording temperature, pressure, and other variables

Complete systems with components assembled on a common baseplate

| Physical Specifications | ||||||

|---|---|---|---|---|---|---|

| Model | Internal Dimensions (ID x Length) | Working Capacity 60% Full (cu ft) | Discharge Opening Dia. (in) | Charge Opening Dia. (in) | Typical Ribbon Speed (rpm) | Typical Motor Horsepower |

| VRD-1520 | 18" x 2'0" | 2.3 | 4 | 6 | 25 | 1 |

| VRD-1740 | 20" x 4'0" | 5 | 4 | 6 | 20 | 1 |

| VRD-2040 | 2'0" x 4'0" | 7 | 6 | 10 | 20 | 1 |

| VRD-2060 | 2'0" x 6'0" | 11 | 6 | 10 | 20 | 1 1/2 |

| VRD-2080 | 2'0" x 8'0" | 14 | 6 | 10 | 20 | 2 |

| VRD-2560 | 2'6" x 6'0" | 17 | 8 | 10 | 20 | 3 |

| VRD-2580 | 2'6" x 8'0" | 23 | 8 | 10 | 15 | 5 |

| VRD-25100 | 2'6" x 10'0" | 29 | 8 | 10 | 15 | 5 |

| VRD-3060 | 3'0" x 6'0" | 24 | 8 | 12 | 15 | 5 |

| VRD-3080 | 3'0" x 8'0" | 32 | 8 | 12 | 15 | 5 |

| VRD-30100 | 3'0" x 10'0" | 39 | 8 | 12 | 15 | 7 1/2 |

| VRD-30120 | 3'0" x 12'0" | 44 | 10 | 12 | 15 | 7 1/2 |

| VRD-30150 | 3'0" x 15'0" | 55 | 10 | 12 | 15 | 10 |

| VRD-4080 | 4'0" x 8'0" | 57 | 10 | 16 | 10 | 7 1/2 |

| VRD-40100 | 4'0" x 10'0" | 70 | 10 | 16 | 10 | 7 1/2 |

| VRD-40120 | 4'0" x 12'0" | 84 | 10 | 16 | 10 | 7 1/2 |

| VRD-40150 | 4'0" x 15'0" | 100 | 12 | 16 | 10 | 15 |

| VRD-40200 | 4'0" x 20'0" | 130 | 12 | 16 | 10 | 15 |

| VRD-50100 | 5'0" x 10'0" | 111 | 12 | 16 | 7 | 15 |

| VRD-50150 | 5'0" x 15'0" | 161 | 12 | 16 | 7 | 20 |

| VRD-50200 | 5'0" x 20'0" | 209 | 12 | 16 | 5 | 20 |

| VRD-50250 | 5'0" x 25'0" | 262 | 12 | 16 | 5 | 25 |

| Larger sizes are available upon request. | ||||||

| Spatial Specifications | ||||

|---|---|---|---|---|

| Model | Approximate Space Occupied by Dryer | Approximate Weight (lb) | ||

| Height | Width | Length | ||

| VRD-1520 | 4'2" | 2'6" | 6'0" | 1,500 |

| VRD-1740 | 4'4" | 2'9" | 9'0" | 2,700 |

| VRD-2040 | 4'6" | 3'0" | 9'0" | 3,100 |

| VRD-2060 | 4'6" | 3'0" | 11'0" | 3,500 |

| VRD-2080 | 4'6" | 3'0" | 13'0" | 3,700 |

| VRD-2560 | 5'0" | 3'6" | 11'0" | 4,500 |

| VRD-2580 | 5'0" | 3'6" | 13'0" | 5,700 |

| VRD-25100 | 5'0" | 3'6" | 15'0" | 6,900 |

| VRD-3060 | 5'6" | 4'0" | 11'0" | 5,500 |

| VRD-3080 | 5'6" | 4'0" | 13'0" | 6,700 |

| VRD-30100 | 5'6" | 4'0" | 15'0" | 7,900 |

| VRD-30120 | 5'6" | 4'0" | 18'0" | 9,100 |

| VRD-30150 | 5'6" | 4'0" | 21'0" | 10,800 |

| VRD-4080 | 6'6" | 5'0" | 13'0" | 10,100 |

| VRD-40100 | 6'6" | 5'0" | 15'0" | 11,500 |

| VRD-40120 | 6'6" | 5'0" | 18'0" | 14,100 |

| VRD-40150 | 6'6" | 5'0" | 21'0" | 17,800 |

| VRD-40200 | 6'6" | 5'0" | 26'0" | 24,000 |

| VRD-50100 | 7'6" | 6'0" | 16'0" | 20,00 |

| VRD-50150 | 7'6" | 6'0" | 21'0" | 25,000 |

| VRD-50200 | 7'6" | 6'0" | 26'0" | 32,000 |

| VRD-50250 | 7'6" | 6'0" | 31'0" | 40,000 |

Replacement Parts and Services

We stock a wide variety of parts for J.P. Devine and McGill Vacuum Dryers. We can also custom fabricate parts from our drawing and data archives for dryers manufactured from 1950 to present.

Parts and Service:

Replacement parts, inspection, preventive maintenance, code repairs, emergency repair servce, coating repairs and replacement, rebuilds and upgrades, and control system upgrades.

Gaskets:

We stock replacement gaskets for all types of pressure vessels manufactured by McGill AirPressure and United McGill, including Biggs autoclaves and J.P. Devine vacuum dryers. These are McGill AirPressure parts, made to McGill AirPressure specifications.

With our in-house splicing machine, we cut and splice gaskets to fit your equipment. Don't wait until you've blown your last gasket. Keep a supply on hand to get your equipment back in operation as fast as possible.

Technical Know-How

Use the chart below to find the gaskets you need. The chart shows standard gaskets in stock. If your type is not shown, we can arrange for custom tooling of an extrusion die and selection of a compound for your application.

Let us help you choose the right gasket type, size, and material. We provide free installation instructions for all gaskets we carry.

| Gasket Cross Section | Order Code |

|---|---|

|

G211 |

| G212 | |

| G213 | |

|

G214 |

|

G215 |

|

G216 |

|

G217 |

|

G218 |

|

G219 |

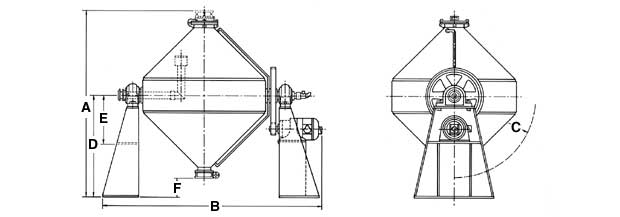

Conical Vacuum Dryers

McGill AirPressure designs and manufactures conical vacuum dryers for drying free-flowing materials that cannot stand attrition. Drying takes place in a conical chamber that rotates end over end to create a gentle folding and mixing action. Vacuum dryers remove moisture by exposing the materials to reduced pressure. Just enough heat is used to replace that lost through vaporization.

Standard working volumes range from 1 to 348 cubic feet. Custom sizes are available on request. Vapor-contacting parts are fabricated from carbon steel, stainless steel, or special alloys.

Conical Drying Applications:

- fine chemicals

- food products

- pharmaceuticals

- powders

- powdered metals

- fibers

- plastics

Material Handling

Material is loaded into the drying chamber through a charge valve with a spring-assisted, hinged cover. The standard discharge valve is a handwheel-operated, butterfly valve design with teflon seats and seals and a stainless steel disc. Options include an air-operated discharge valve and unloading boot.

Conical Vacuum Dryer Operation

The standard operating pressure is one torr. Constant-speed and variable-speed drives are available in chain-and-sprocket, gear-and-pinion, or direct-drive designs with guards. Stuffing box and single mechanical seals are available, with an internal lip-type shaft seal on the vacuum line. A double mechanical seal can be used on the vacuum line for operation to 50 microns mercury. Dryers are equipped with self-aligning, anti-friction bearings on trunnions. An oversized rotary joint and jacket connections for the liquid heating medium are available. An internal thermocouple can be supplied for measuring product temperature.

Construction of Conical Vacuum Dryers

Conical dryers are available with all vapor-contacting parts made of carbon steel, stainless steel, or special alloys. Internal welds are ground smooth, and internal surfaces can be finished with a 30-50 micro-inch polish. External surfaces can be painted or insulated with a polished stainless steel cover.

The dryer jacket is designed and stamped in accordance with ASME code for 25, 50, or 100 psig, coincidental with full vacuum in dryer. The jacket is baffled for equal distribution of the liquid heating medium.

Special bronze bearings provide internal support of the vacuum line, which is equipped with an intake filter formed of multiple layers of stainless steel mesh (special vacuum line filters are available). Conical dryers are equipped with a vacuum gauge, vacuum release valve, jacket pressure gauge, and jacket relief valve. A bronze double rotary joint is provided for steam and condensate connections.

Floor stands and stub stands are available.

Auxiliary Equipment Options for Rotary Vacuum Dryers

Vertical shell and tube surface condensers

Refrigerated or dry-ice traps

Vacuum pumping systems: mechanical, water-sealed, or steam jet

Heating systems: steam, water, oil, or other fluid

Cooling systems: direct or indirect

Bag-type vacuum dust collectors with controls for intermittent shaking or pulsing of material back into the dryer

Dust-tight discharge hoppers and valves for filling containers

Instrumentation for process control and documentation: fully wired control panels or field mounted individual instruments for sensing, indicating, or recording temperature, pressure, and other variables

Complete systems with components assembled on a common baseplate

Standard Specifications for McGill AirPressure Conical Vacuum Dryers

| Physical Specifications | |||||||

|---|---|---|---|---|---|---|---|

| Model |

Working Capacity 70% Full (cu ft) |

Charge Opening Dia. (in) |

Discharge Opening Dia. (in) |

Dryer Rev. per Minute |

Motor Horsepower |

Max. Apparent Density (lb/cu ft) |

Vacuum Line Size (in) |

| VCD-15 | 1.1 | 6 Combination | 12 | 1/4 | 150 | 1 | |

| VCD-20 | 2.9 | 6 Combination | 11 | 1/4 | 150 | 1 1/2 | |

| VCD-25 | 5.1 | 8 | 6 | 10 | 1/3 | 100 | 1 1/2 |

| VCD-30 | 8.6 | 8 | 6 | 9 | 1/2 | 100 | 2 |

| VCD-35 | 14.3 | 16 | 8 | 8.5 | 3/4 | 90 | 2 |

| VCD-40 | 20.3 | 16 | 8 | 8 | 1 | 75 | 3 |

| VCD-45 | 29.0 | 16 | 8 | 7.5 | 1 1/2 | 75 | 3 |

| VCD-50 | 39.8 | 16 | 10 | 7 | 2 | 70 | 3 |

| VCD-60 | 72.2 | 16 | 10 | 6.5 | 3 | 55 | 3 1/2 |

| VCD-70 | 109.6 | 16 | 10 | 6 | 5 | 50 | 3 1/2 |

| VCD-80 | 163.9 | 16 | 10 | 5.5 | 7 1/2 | 50 | 6 |

| VCD-90 | 233.3 | 18 | 12 | 4.5 | 10 | 50 | 6 |

| VCD-105 | 347.9 | 18 | 12 | 3.75 | 15 | 50 | 6 |

| Spatial Specifications | |||||||

|---|---|---|---|---|---|---|---|

| Model |

Approximate Floor Space |

Overall Height A (in) |

Overall Length B (in) |

Swing Radius C (in) |

Floor Stands D (in) |

Stub Stands E (in) |

Valve Clearance F (in) |

| VCD-15 | 2'6" x 4'0" | 46 | 62 7/8 | 14 | 32 | — | 18 |

| VCD-20 | 3'0" x 5'6" | 56 | 76 3/4 | 19 | 37 | — | 18 |

| VCD-25 | 3'9" x 6'0" | 61 7/8 | 83 3/8 | 23 3/4 | 38 1/8 | — | 18 |

| VCD-30 | 4'6" x 7'0" | 70 7/8 | 91 3/8 | 28 1/4 | 42 5/8 | — | 18 |

| VCD-35 | 5'0" x 7'6" | 82 1/4 | 98 7/8 | 35 1/4 | 47 | — | 18 |

| VCD-40 | 5'6" x 8'0" | 88 1/4 | 103 1/4 | 38 1/4 | 50 | — | 18 |

| VCD-45 | 6'0" x 9'0" | 96 | 118 3/8 | 42 1/4 | 53 3/4 | — | 18 |

| VCD-50 | 6'6" x 10'0" | 102 1/4 | 125 1/4 | 45 1/4 | 57 | — | 18 |

| VCD-60 | 7'9" x 11'6" | — | 139 5/8 | 53 3/4 | — | 18 | — |

| VCD-70 | 9'0" x 12'6" | — | 147 7/8 | 60 1/4 | — | 18 | — |

| VCD-80 | 10'9" x 13'6" | — | 166 1/8 | 67 3/4 | — | 36 | — |

| VCD-90 | 14'0" x 18'0" | — | 183 7/8 | 74 3/4 | — | 36 | — |

| VCD-105 | 16'0" x 22'0" | — | 204 1/4 | 83 3/4 | — | 36 | — |

Replacement Parts and Services

We stock a wide variety of parts for J.P. Devine and McGill Vacuum Dryers. We can also custom fabricate parts from our drawing and data archives for dryers manufactured from 1950 to present.

Parts and Service:

Replacement parts, inspection, preventive maintenance, code repairs, emergency repair servce, coating repairs and replacement, rebuilds and upgrades, and control system upgrades.

Gaskets:

We stock replacement gaskets for all types of pressure vessels manufactured by McGill AirPressure and United McGill, including Biggs autoclaves and J.P. Devine vacuum dryers. These are McGill AirPressure parts, made to McGill AirPressure specifications.

With our in-house splicing machine, we cut and splice gaskets to fit your equipment. Don't wait until you've blown your last gasket. Keep a supply on hand to get your equipment back in operation as fast as possible.

Technical Know-How

Use the chart below to find the gaskets you need. The chart shows standard gaskets in stock. If your type is not shown, we can arrange for custom tooling of an extrusion die and selection of a compound for your application.

Let us help you choose the right gasket type, size, and material. We provide free installation instructions for all gaskets we carry.

| Gasket Cross Section | Order Code |

|---|---|

|

G211 |

| G212 | |

| G213 | |

|

G214 |

|

G215 |

|

G216 |

|

G217 |

|

G218 |

|

G219 |